CYTOTOXIC DRUG SAFETY CABINET TESTING

HEPA FILTER TESTING

/

FUME CUPBOARD TESTING

/

BIOLOGICAL SAFETY CABINETS

/

CLEAN WORK STATIONS

/

CYTOTOXIC DRUG SAFETY CABINET TESTING

/

CLEANROOM VALIDATION

/

HEPA FILTER TESTING / FUME CUPBOARD TESTING / BIOLOGICAL SAFETY CABINETS / CLEAN WORK STATIONS / CYTOTOXIC DRUG SAFETY CABINET TESTING / CLEANROOM VALIDATION /

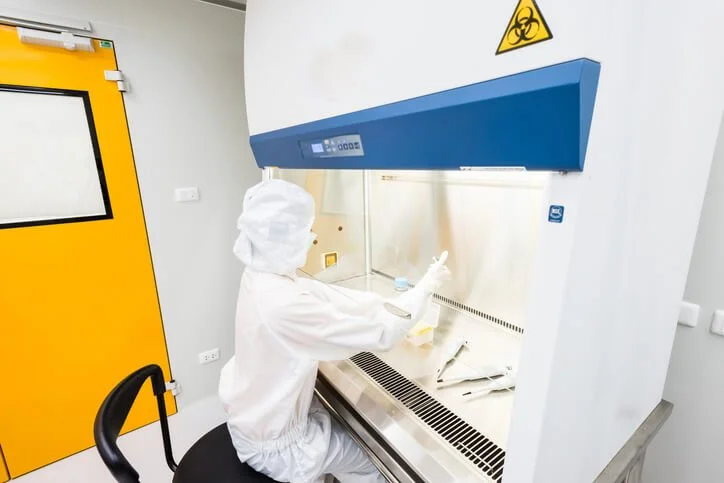

Cytotoxic Drug Safety Cabinets (CDSCs) provide the primary barrier against exposure to hazardous aerosols released during the preparation, handling, and dispensing of cytotoxic drugs. Regular testing is essential to ensure these cabinets continue to protect staff and the surrounding environments.

Why Testing is Essential

Without proper testing, CDSCs may expose personnel to dangerous particles that accumulate within filters and mechanical components, or allow contaminants to spread into adjacent work areas.

Personnel Protection - Safeguards maintenance staff from exposure to accumulated drug particles that contaminate filters and mechanical components.

Environmental Safety - Protects surrounding areas and personnel not involved in cytotoxic drug preparation and use.

When do you test cytotoxic drug safety cabinets?

Testing is required at the following intervals:

Initial commissioning: On-site prior to first use.

After relocation: When cabinets are moved to new locations.

Post maintenance: After mechanical or electrical maintenance, including HEPA filter replacement.

Annual certification: At least every 12 months for ongoing compliance.

AG&G Services provides comprehensive certification in accordance with AS 2252.5 (2017). Testing covers both performance and operational safety:

Compliance Test Requirements

-

Air velocity and uniformity in the work zone

Work zone integrity verification

HEPA filter installation integrity

Air classification particle counting (ISO 5)

Air barrier containment assessment

-

Noise level measurement

Luminance verification

Alarm checks (where applicable)

UV radiation intensity (where applicable)

AG&G Services is NATA-accredited to certify CDSCs to the highest standards.

This ensures your cabinets provide effective protection for personnel, environments, and compliance requirements.