CLEANROOM VALIDATION

HEPA FILTER TESTING

/

FUME CUPBOARD TESTING

/

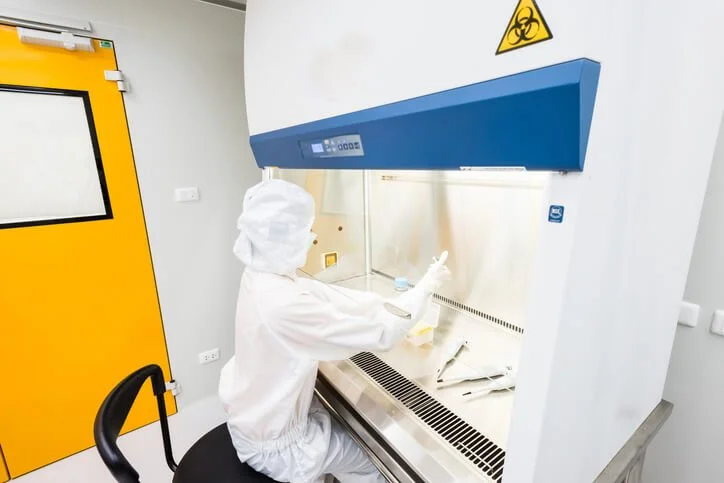

BIOLOGICAL SAFETY CABINETS

/

CLEAN WORK STATIONS

/

CYTOTOXIC DRUG SAFETY CABINET TESTING

/

CLEANROOM VALIDATION

/

HEPA FILTER TESTING / FUME CUPBOARD TESTING / BIOLOGICAL SAFETY CABINETS / CLEAN WORK STATIONS / CYTOTOXIC DRUG SAFETY CABINET TESTING / CLEANROOM VALIDATION /

Cleanrooms and contamination-controlled environments - including operating theatres, isolation rooms, and sterile processing areas - are engineered to regulate particulates and environmental conditions. These critical spaces rely on HEPA filtered air and pressure systems to maintain cleanliness levels that protect patients, staff, and products.

Why Is Certification

Critical?

Regular inspections, testing, and certification ensure your facility remains safe, compliant, and operational.

Patient Safety: In hospitals, operating theatres and sterile processing areas directly impact patient outcomes and infection control.

Personnel Protection: Cleanrooms, workstations and safety cabinets serve as essential barriers against airborne contamination.

Regulatory Compliance: Healthcare facilities must meet stringent Australian and international standards for contamination control.

-

Our cleanroom validation follows AS/ISO 14644.2 and AS 1807.x methods, including:

Air velocity and uniformity in work zones.

HEPA filter installation integrity verification (AS/ISO 14644.3 B6 & 7.4).

Air cleanliness classification by particle counting (AS/ISO 14644.1:2017Room pressure differential measurement.

Recovery time testing (Grade C and above).

Smoke visualisation in compliance with AS/ISO 14644.

-

To optimise performance, we also offer:

Environmental comfort checks (temperature, humidity, noise, and luminance).

Airflow and pressure system optimisation.

Magnehelic gauge calibration.

New cabinet/isolator IOPQ validation.

-

Hospital and healthcare facilities present complex environments requiring specialised knowledge. AG&G Services has extensive experience validating critical areas including:

Operating theatres: Surgical suite contamination control.

Isolation rooms: Infection control environments.

Sterile stores and CSSD: Central sterilisation departments.

ICU and critical care areas: Patient protection environments.

Our healthcare validation follows AS 1668.2, DHS and NSW guidelines, and all applicable Australian and international standards, ensuring facilities meet the highest safety and compliance requirements.

AG&G Services provides the assurance that your cleanrooms and contamination-controlled environments meet the standards required to protect patients, staff and operations.

What makes us different

/04

CUSTOM PROTECTION PLANS

Maintenance programs tailored to your operations and risk profile.

/05

TRIPLE-CERTIFIED EXCELLENCE

Three NATA signatories ensure consistent, reliable service delivery.

/06

CUSTOMER-FIRST PHILOSOPHY

Responsive service and a focus on ensuring your needs meet evolving contamination control standards.

/01

FORENSIC DOCUMENTATION

Every test report is audit-ready, with calibrated equipment, references and detailed analysis.

/02

STRATEGIC INSIGHTS

We identify optimisation opportunities and recommend preventative measures before issues arise.

/03

QUALITY GUARANTEE

Replacement parts always meet or exceed original specifications.

AG&G Services provides the assurance that your cleanrooms and contamination-controlled environments meet the standards required to protect patients, staff, and operations.